Automatic Bending and Welding Production Line For Back of Metal Cabinet

Automatic Bending and Welding Production Line For Back of Metal Cabinet

Pallet Shuttle Rack System

1. Specification

No. | Name | parameters | Remark |

1 | Height of Equipment | From the ground 850±50mm |

|

2 | Size of Equipment | Length X Wide: about 11,000 X4300mm |

|

3 | Product Range | L=2100mm,W=950mm(finished) |

|

4 | Output Capacity | ≤65s/Set | Average |

5 | Material Scope | Q345B |

|

6 | Thickness | 0.5mm-0.8mm |

|

7 | About 50KVA(380V,50Hz) |

| |

8 | 0.6~0.8MPa |

| |

9 | -5℃-40℃ |

| |

10 | Machining accuracy | The limit deviation accuracy of the dimensions without tolerance in the drawing is according to GB1804-m |

|

11 | control system | SYNTEC (Made in Taiwan) |

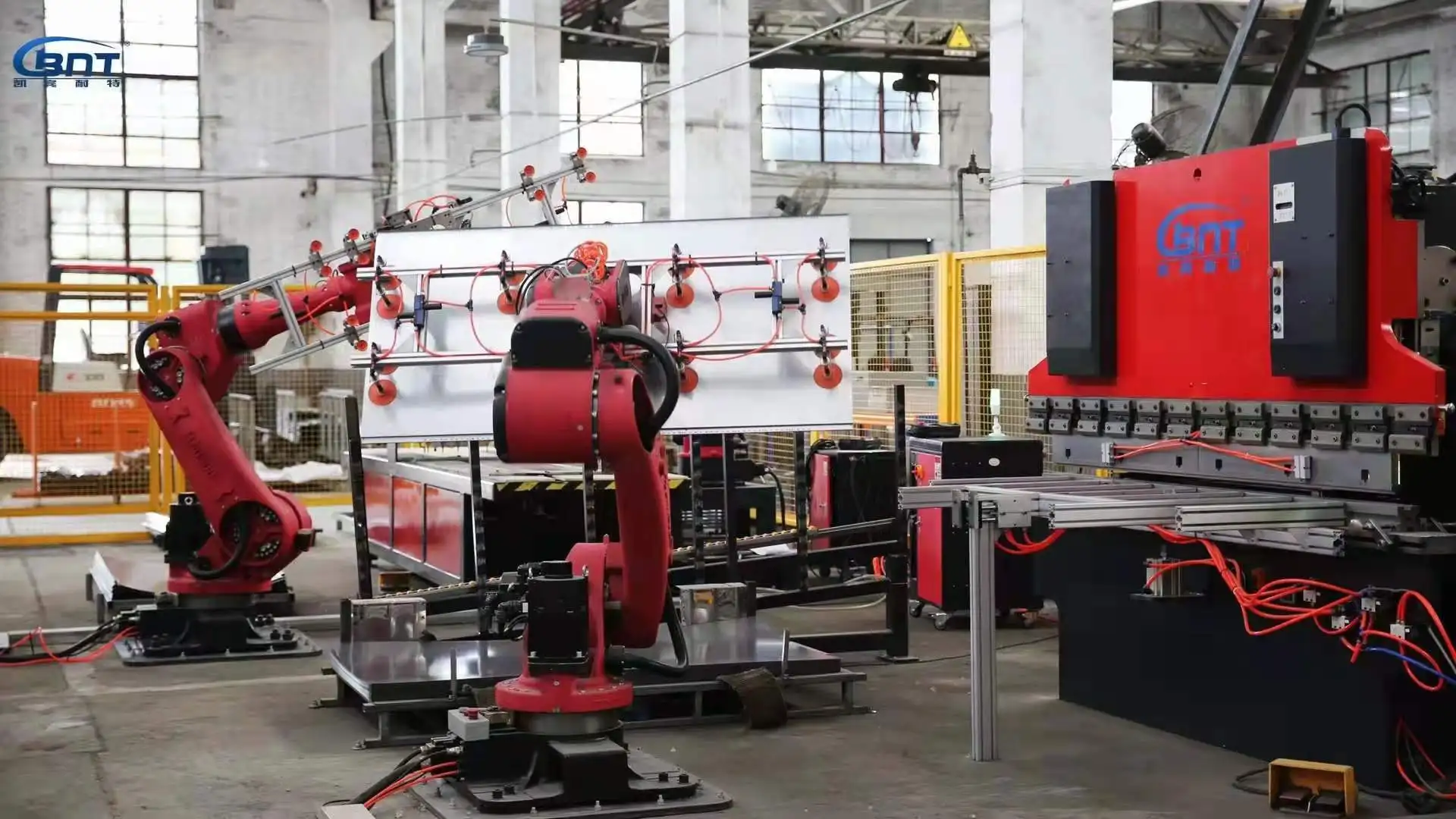

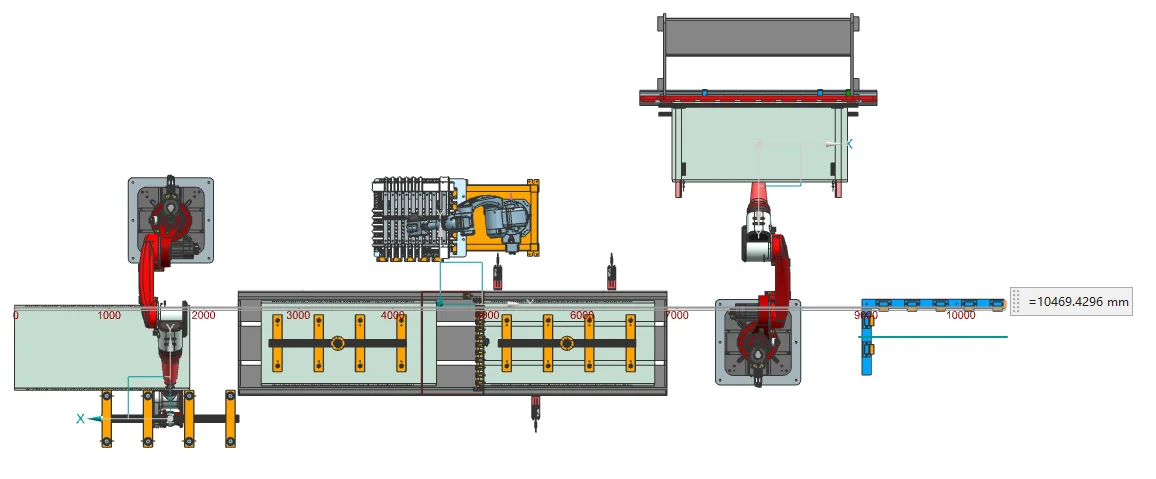

This scheme is the basis of the product drawings provided by Luoyang CBNT Automation Equipment Co., Ltd. to protocol the preliminary technical proposal and quotation. Our forming line is mainly composed of a feeding spreading platform, moving splitting robot, bending center and auxiliary platform, 180-degree turning platform, welding line, reinforcing bar case, reinforcing bar loading robot, uploading robot, pneumatic system, hydraulic system, electric control system and so on.

Application: high volume production of the back of the metal cabinet

Process flow: Feeding —— Bending —— 180 degree inverted ——Reinforcement bar loading —— Welding line —— Unloading

2. Overall Layout Diagram:

3. UN2000hbzhscx Back folding welding production line configuration

Name | parameters | Others | |

1 | Bend mold upgrade | Power of upper and lower mold 3KN | CBNT |

2 | Auxiliary Bending Lifting platform | Length X Wide:About 2000X1000mm | CBNT |

3 | Turning platform | Length X Wide:About 2000X1000mm | CBNT |

4 | reinforcing bar case | case A case B | CBNT |

5 | Feeding robot | BRTIRUS2550A 50KG | BRTIRUS |

6 | reinforcing bar loading robot | BRTIRUS | |

7 | welding line system upgrade version |

| CBNT |

8 | Unloading truss robot | UENON5015A 50KG | UENON |

9 | pneumatic system | AirTAC |

|

10 | Hydraulic lubrication system |

|

|

11 | Electronic control system | SYNTEC (Made in Taiwan) |

|

SUPPLY ABILITY AND TRADING TERMS

Terms of payment

-T/T, 10% deposit before design the drawing draft, 60% before production, 20% before loading, 10% the balance after the adjustment and installation.

Lead-time

1.Design picture draft: 2 weeks

2.Production line: 3 months

3.Technical training: 1 week. The company can also provide in-door installation, equipment debugging, technical training services, to guide the plant establishment and production.

APPLICATION

Company / Factory / Storage / Workshop/ Production Department/ Manufacturing shop

-

Automatic Bending and Welding Production Line For Back of Metal Cabinet其他$500000起享受工厂价

Automatic Bending and Welding Production Line For Back of Metal Cabinet其他$500000起享受工厂价 -

High Quality Steel Four Layers Shoes Cabinet Steel Storage鞋柜$28起享受工厂价

High Quality Steel Four Layers Shoes Cabinet Steel Storage鞋柜$28起享受工厂价 -

Intelligent 3 In 1 CNC Equipment其他$500000起享受工厂价

Intelligent 3 In 1 CNC Equipment其他$500000起享受工厂价 -

Automatic bending and welding production line for side of metal cabinet其他$500000起享受工厂价

Automatic bending and welding production line for side of metal cabinet其他$500000起享受工厂价